I expect yopu've all had sleepless nights worrying about how I've been getting on with the project. Fear not - all will be revealed.

I'm still waiting with my fingers crossed for my V5C to arrive. They haven't cashed my cheque yet. So am occupying myself by doing various dry (and wet) builds of the engine. I've now completed the bottom end - some of which is odd to my mind. As well as giving a torque figure for the big end nuts Triumph also specify a stretch on the bolt of .004" to .005". I think I've got it right....

Despite having mismatched crankcases from different years not to mention different capacities, the bottom end and timing gear has all gone together remarkably well. There's no perceptible step between the case sides at the barrel face and the crank and camshafts all spin easily. So I'm hopeful about that side.

Less so about the notorious pushrod tube sealing which has had me scratching my head for ages. There is an annular seal at the bottom of the tube which fits over the tappet block and a Viton ring which sits in the head to seal the top flange of the tube. The book and all the "experts" I've consulted say there should be .040" - .060" "crush" on this top ring when the head is bolted down. However, assembling with no seals at all leaves the head floating .040" or so above the barrel face - which coincidentally is close to the thickness of the head gasket. I measured this using plasticine in the joint and tightening the head down with no gasket.

Obviously, putting seals in would mean that there would be no clamping force on the head gasket at all. So after much thought I've decided to turn .060" off the bases of the pushrod tubes to allow them to sit further down and get this crush. What can possibly go wrong? More to the point, why do I need to do this? My only theory is that the head face has been skimmed at some point. Remember that this engine is being built from a fairly random selection of bits which someone else has discarded after selecting better ones.

Just looking at the photos I have to make sure that the reduced portion of the tube won't catch on the tappet block. And of course I will have to deal with any effects on valve / pushrod geometry if as I suspect the head has been skimmed.

Some photos:

This is the barrel after tightening down the head showing the flattened plasticine.

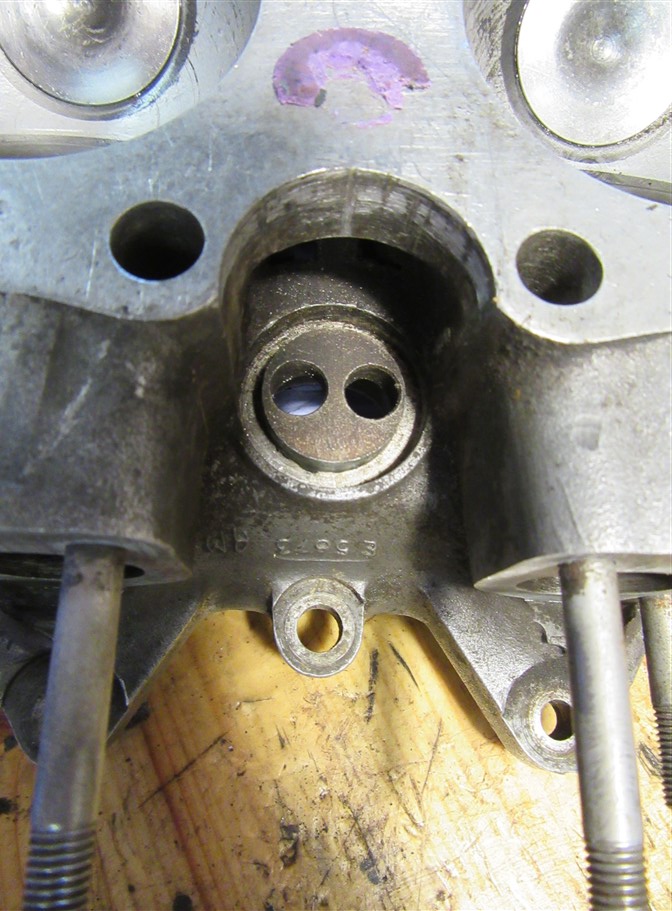

This shows how the pushrod tube sits on the tappet block.

Another view showing the flange at the top of the tube and the (annealed) head gasket - which by the way was rock hard when it arrived.

This is the recess in the head that the flange fits into.

The first pushrod tube in the 4 jaw chuck - it's too big for the 3 jaw.

And this is the Viton sealing ring which is .090" thick uncompressed.